Re-Configuring America’s Supply Chains

American businesses are increasingly examining their supply chains to reduce their reliance on Chinese sourcing. This was catalyzed by the trade war between China and the U.S., and accelerated by the coronavirus (COVID-19) pandemic.

To view the full article please register below:

Re-Configuring America’s Supply Chains

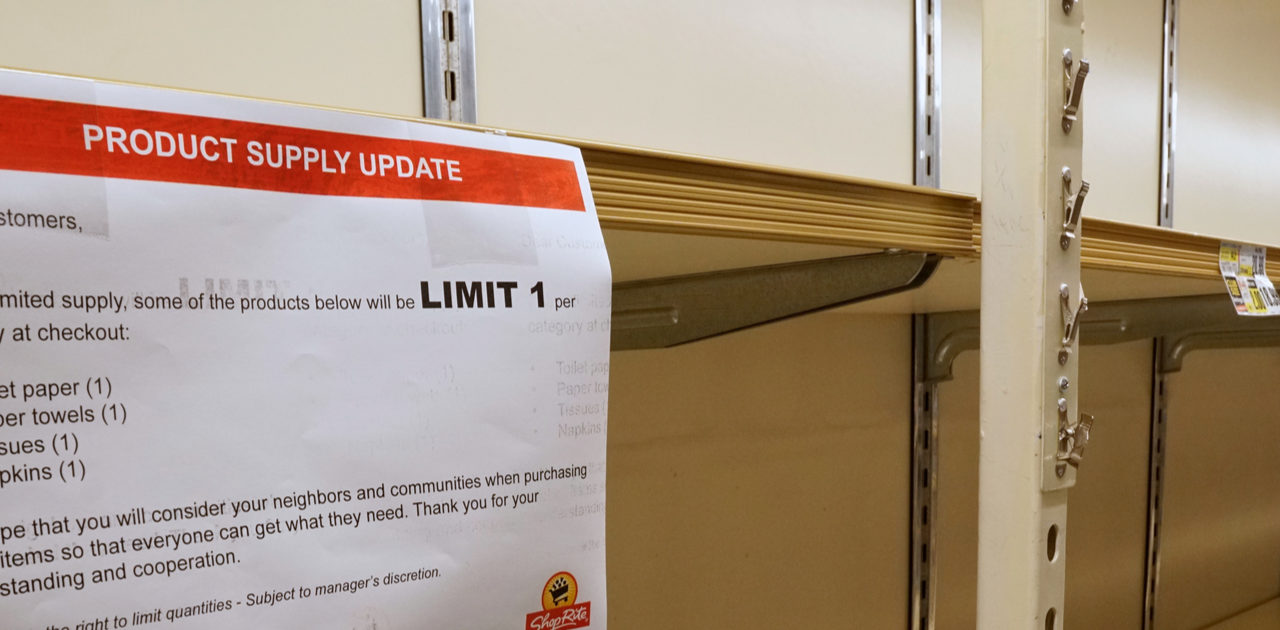

Catalyzed by the trade war between China and the U.S., and accelerated by the coronavirus (COVID-19) pandemic, American businesses are increasingly examining their supply chains to reduce their reliance on Chinese sourcing and enhance their resiliency against unforeseeable events like a pandemic or an outbreak of geopolitical hostilities.

Companies are not alone in feeling compelled to de-risk their supply changes. The U.S. government appears ready to address the national strategic implications of an overreliance on foreign manufacturing for important products, a concern that surfaced during the pandemic. Chief among these concerns is the dependence on China for the production of personal protection equipment and pharmaceuticals.

Many companies have already begun to examine their Tier 1 suppliers to gauge the feasibility of relocating their production to other locations, such as Mexico, India, and Brazil. This re-examination won’t be limited to changing country locations. It is also likely to include steps to diversify Tier 1 suppliers in order to reduce dependence on a single manufacturer. This analysis will in many cases extend to Tier 2 suppliers, upon which Tier 1 suppliers rely to supply the parts needed to manufacture end products.

“Just in time” inventory practice is coming to an end. While the “just in time” approach was once viewed as a financially astute way to manage cash flow, it has shown itself to be highly vulnerable to disruptions. Companies are learning that maintaining higher inventory levels is smart risk management.

Obstacles to Overcome

American companies confront a number of obstacles as they look to bring manufacturing back to the United States or relocate it to other nations. For many countries, including the U.S., infrastructure will need to be built or upgraded. Worker training and development will be necessary to address a shortage of skilled workers. Tax and regulatory issues may also prove to be high hurdles in certain countries and domestic locations. In the U.S., strict immigration policy looms as a potential problem given a deceleration in the U.S. birth rate that may lead to a shortage of young workers to fill the returning manufacturing jobs.

Supply Chain 2.0

Similar to nearly every aspect of our lives, supply chains will become more digitally based. Enabling technology—IoT, cloud computing, AI, 5G, 3D printing, robotics—will foster agile supply chains that should provide greater responsiveness to future health and economic disruptions. On this journey expect that company profits may be adversely affected, while new investment opportunities may arise with companies well-positioned to profit from the reconfiguration of supply chains.

Please reference disclosures: https://blog-dev.americanportfolios.com/disclosures/